| Pallet Rack Box Beam Roll Forming Machine | ||

|---|---|---|

| Machinable Material : | A) Galvanized Coil B) PPGI C) Cold-rolled Steel D) Stainless Steel E) Aluminum F) Carbon steel |

Thickness(MM):1.5-2.0 |

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | 350 Mpa-500 Mpa | |

| Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 18-20 | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Torri stands | * Cast iron stands (Optional) |

| Rollers’ material : | GCr15 | * SKD-T1 (Optional) |

| Cutting system : | Hydraulic cut | * Flying cut (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

Product Overview

Our Upright Roll-Forming Machine, also called the pallet-shelf roll forming line by Xinnuo, is specially designed for producing strong shelving rack uprights with thicknesses ranging from 1.5–3.0 mm. The fully automatic line includes decoiling, servo feeding, punching, roll forming, and hydraulic shearing — all controlled via PLC / HMI for streamlined production.

Key Features of the Upright Machine

One machine supports multiple profile sizes, with either automatic size changeover or optional manual changeover.

Tooling made from high-chrome bearing steel (EN31) and tool steel (D3) for durability.

Overflow coolant system ensures high-quality surface finish.

Hydraulic cutting press for precise and clean cuts.

Closed-loop cut-to-length system for consistent part dimensions.

All electrical components use aviation-grade quick-connect plugs — easy to install and maintain.

Benefits

Interchangeable roller kits extend roller life.

Continuous operation boosts productivity.

Tight tolerances ensure consistent, high-quality uprights.

Easy installation and low maintenance requirements.

| Pallet Rack Box Beam Roll Forming Machine | ||

|---|---|---|

| Machinable Material : | A) Galvanized Coil B) PPGI C) Cold-rolled Steel D) Stainless Steel E) Aluminum F) Carbon steel |

Thickness(MM):1.5-2.0 |

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | 350 Mpa-500 Mpa | |

| Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 18-20 | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Torri stands | * Cast iron stands (Optional) |

| Rollers’ material : | GCr15 | * SKD-T1 (Optional) |

| Cutting system : | Hydraulic cut | * Flying cut (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

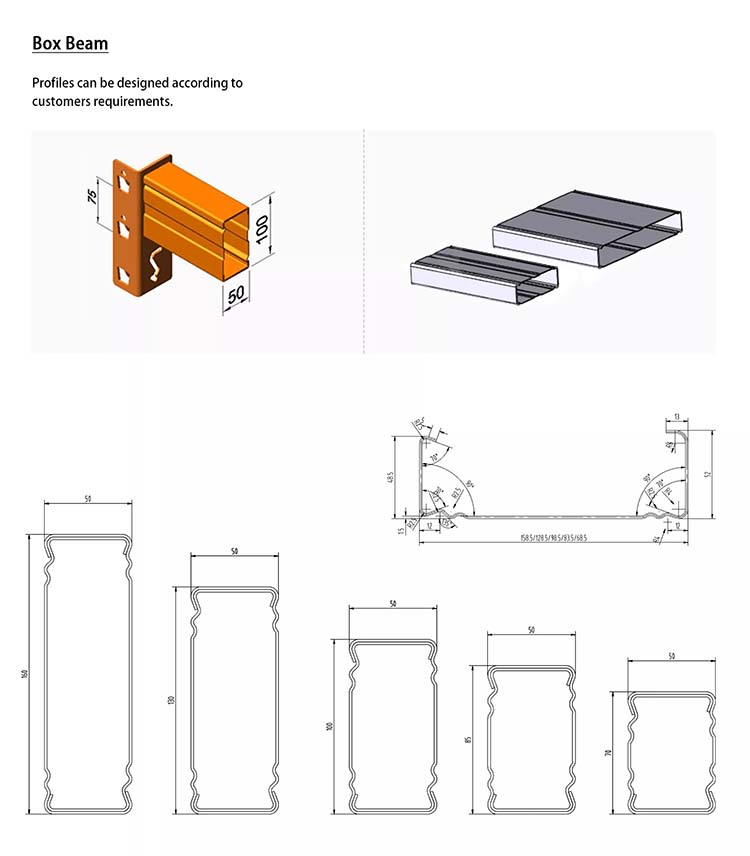

Box Beam Solution

Xinnuo also provides a Box Beam Roll-Forming Machine designed to manufacture load-bearing box-type beams for rack systems. Its forming speed ranges from 10 to 20 m/min, adjustable to your needs:

Dimensions:

Height 40 mm; widths: 85 / 100 / 125 mm

Height 50 mm; widths: 80 mm up to 300 mm

Size is adjusted via a servo motor (when the line is empty), and length is set through the touch-screen on the control cabinet.

No welding needed — profiles are cleanly formed and seamed.

Compatible materials: cold-rolled steel, galvanized steel, PPGI, carbon steel, stainless steel, and aluminum; thickness from 1.5 mm to 2.0 mm.

Customization & Service

Our team can develop a solution tailored to your drawings, tolerance requirements, and budget. There is also a manual size-change option (adjusting spacers on the rollers) to reduce machine costs when needed.

All our operating systems and manuals are available in English and Spanish, enabling your team to operate the machines safely and efficiently.

Why Choose Xinnuo

Integrated solution: Uprights + Box Beams + Step Beams + Shelf Panels — all under one roof.

High automation reduces labor and error, resulting in higher throughput.

Extensive export experience: Xinnuo has supplied roll forming lines to clients worldwide and offers customized, drawing-based solutions.