| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel / Galvanized steel |

| Material thickness | ~ 1.5 – 2.5 mm (customizable) |

| Material width | Based on shelf/rack profile design (e.g. 100–500 mm) |

| Forming stations | 16 – 28 stations (depending on profile & configuration) |

| Forming speed | 10 – 15 m/min (with punching/cutting) |

| Roller material | GCr15 steel, heat-treated & chromed/hardened |

| Drive system | Gearbox drive or chain drive |

| Cutting / Punching system | Hydraulic or servo cutting + optional inline punching |

| Control system | PLC + HMI touchscreen — automatic length, quantity, cut & punch control |

| Power supply / Voltage | 380 V, 50 Hz, 3-phase (customizable) |

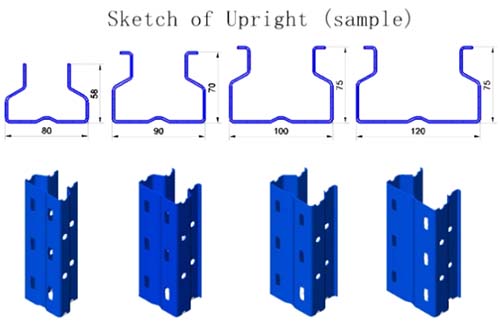

| Profile types / Output | Upright rack posts, shelf beams, storage rack components |

| Cutting / Length tolerance | ±1 – ±2 mm (depending on configuration) |

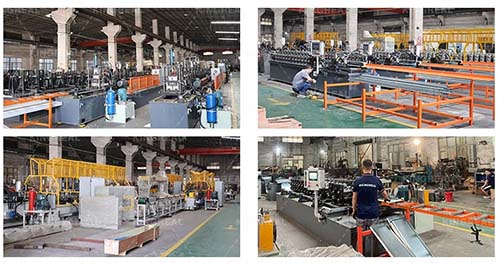

Our Steel Shelving Rack Roll Forming Machine is designed to deliver high-efficiency, flexible production of shelving rack components from galvanized or cold-rolled steel. Whether you need standard racks for supermarkets, warehouses, or industrial storage systems, this machine adapts to your requirements — producing upright posts, shelf beams, and rack frames with precision and consistency.

Full roll forming line: The line integrates a decoiler, feeding & leveling device, punching unit, main forming mill and hydraulic post-cutter — making it a complete solution for shelving rack production.

Automatic & continuous production: Controlled by inverter for motor speed and PLC system for length and quantity — the Steel Shelving Rack Roll Forming Machine achieves continuous automated rolling, punching and cutting.

Material versatility: Accepts galvanized steel or cold-rolled steel coils; suitable for various shelf rack designs (uprights, beams, etc.).

High precision and efficiency: Consistent forming and clean cutoffs ensure high-quality outputs that meet strict rack manufacturing standards.

Customizable and customer-oriented: We welcome customers to provide samples or color rings so that we can produce according to your exact specifications.

| Parameter | Specification |

|---|---|

| Raw material | Cold-rolled steel / Galvanized steel |

| Material thickness | ~ 1.5 – 2.5 mm (customizable) |

| Material width | Based on shelf/rack profile design (e.g. 100–500 mm) |

| Forming stations | 16 – 28 stations (depending on profile & configuration) |

| Forming speed | 10 – 15 m/min (with punching/cutting) |

| Roller material | GCr15 steel, heat-treated & chromed/hardened |

| Drive system | Gearbox drive or chain drive |

| Cutting / Punching system | Hydraulic or servo cutting + optional inline punching |

| Control system | PLC + HMI touchscreen — automatic length, quantity, cut & punch control |

| Power supply / Voltage | 380 V, 50 Hz, 3-phase (customizable) |

| Profile types / Output | Upright rack posts, shelf beams, storage rack components |

| Cutting / Length tolerance | ±1 – ±2 mm (depending on configuration) |

Decoiler → Leveler / Straightener → Servo Feeding → Punching Device → Main Roll Forming → Hydraulic Cutting → Finished Shelving Rack Components

We uphold the principle of “Survival by Quality, Development by Service, Benefit by Reputation,” ensuring high-quality machines, reasonable prices, and skilled support.

Our experience and manufacturing capability guarantee reliable equipment for metal shelving rack production.

We offer flexible customization — whether it's material, profile shape, size, or control system — to meet diverse client needs.

With a robust roll forming production line like Steel Shelving Rack Roll Forming Machine, you can efficiently produce shelving racks for supermarkets, warehouses, retail storage, and industrial shelving systems.