Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

|

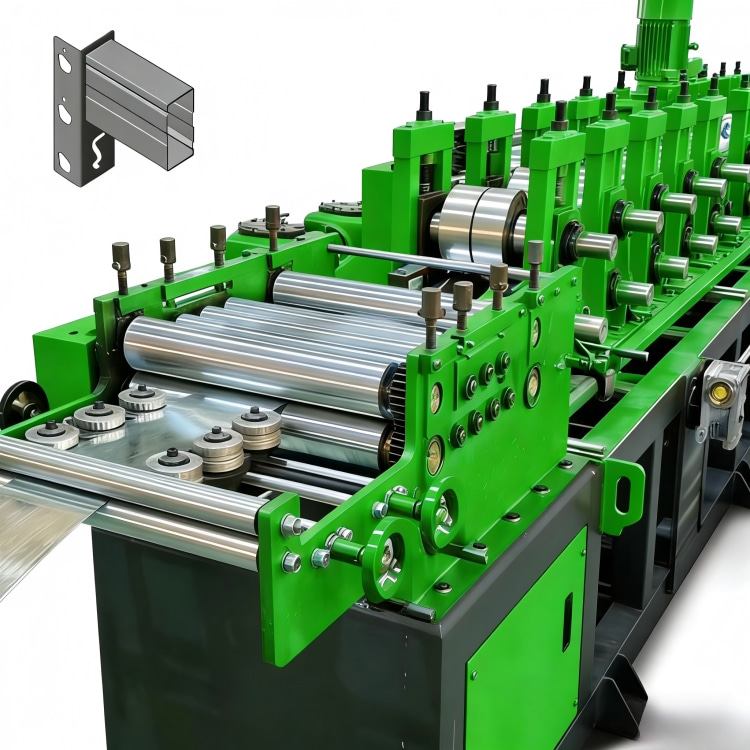

Automatic Box Beam Roll Forming Line |

||

|

Machinable Material |

A) Galvanized Coil |

Thickness(MM):1.5-3.0 as per customer |

|

|

B) Cold/Hot-rolled Steel |

|

|

|

C) Carbon Steel |

|

|

Yield Strength |

250 - 350 Mpa |

|

|

Tensil Stress |

350 Mpa-500 Mpa |

|

|

Nominal Forming Speed(M/Min) |

10-20 |

* Or According To Your Requirment |

|

Forming Station |

18-20 |

* According To Your Profile Drawings |

|

Decoiler |

Manual Decoiler |

* Hydraulic Decoiler (Optional) |

|

Driving System |

Chain Drive |

* Gearbox Drive (Optional) |

|

Machine Structure |

Steel Plates Welded |

* Cast Iron Stands (Optional) |

|

Rollers’ Material |

GCr 15 |

* Cr12Mov (Optional) |

|

Cutting System |

Hydraulic Cut |

* Saw Cut (Optional) |

|

Boxing Unit |

By Chain |

* By Gearbox (Optional) |

|

Welding Efficiency |

Specification 50*100±25 seconds/pcs, |

|

|

Welding &Stacking Process |

Stack the hanging pieces in order on the automatic hanging piece feeding platform,then input the signal,the machine starts to automatically load the hanging pieces,and at the same time,the robot automatically grabs the crossbeam to the specified position of the machine platform,starts welding,first welds the two sides,rotates 90 degrees and then welds the two sides to complete the welding,rotates to another station,and the robot takes the material to the finished product stacking,and the robot takes the material again,and the above actions are repeated. All the above actions are controlled and operated by the dedicated system for the crossbeam automatic line |

|

|

Machine Color |

Industrial Blue |

* Or According To Your Requirment |