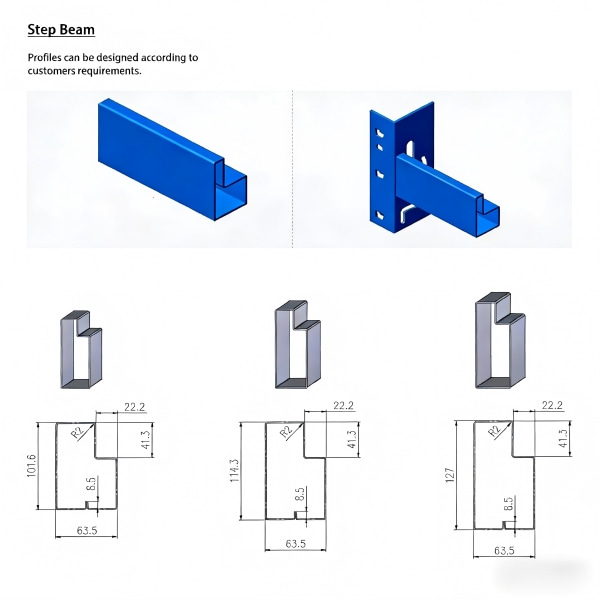

Step Beam Roll Forming Machine

Step beam roll forming machine also named P type beam Roll Forming Machine (s) is developed to produce the beam which is fixed between the upright racks.

Contact Person: XN Duan

Mobile Phone:18832797029

WhatsApp:+86 18832797029

E-mail:yuankuoduan@gmail.com

Add:Zhenggang Road, Industrial Development Zone, Botou City, Hebei Province

Step beam roll forming machine also named P type beam Roll Forming Machine (s) is developed to produce the beam which is fixed between the upright racks.

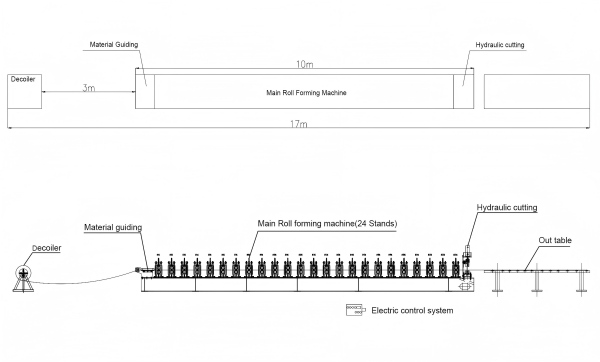

Our intelligent Pallet Racking Step Beam P Beam Roll Forming Machine could make various sizes of beam with thickness 1.5-3.0mm. Uncoiling, feeding, roll forming, welding, cutting etc process can be automatically realized on one line. Meantime, we have the roll forming machine to make box beam, upright rack and shelf panels. All these are components of Pallet racking system.

Step beam roll forming machine also named P type beam Roll Forming Machine (s) is developed to produce the beam which is fixed between the upright racks.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

What is beam roll forming machine?

A beam roll forming machine is a type of industrial machinery used to manufacture beams with consistent shapes and sizes. Beams are structural elements used in construction and engineering projects to provide support and distribute loads.

The roll forming process involves passing a flat strip of metal through a series of rollers that progressively bend and shape the metal into the desired beam profile. The rollers have specific contours and designs that form the metal strip into the desired shape. The process is continuous, and the machine can produce beams of various lengths.

The specifications of a beam roll forming machine can vary depending on the desired beam profile, such as I-beams, H-beams, or C-beams, and the required dimensions and thickness of the beams. The machine’s capacity and capabilities will determine the maximum size and thickness of the beams it can produce.